Milk and dairy products are the result of a complex production process. The producer must take into account many nuances, apply the necessary equipment, use different auxiliary materials and technologies. Milk and dairy products production is an important part of the food industry, requiring strict quality control at all stages of work.

Technology features:

- Compliance with sanitary standards (temperature, humidity, ventilation, etc.);

- Compliance with fire regulations and sanitary and epidemiological rules;

- The use of quality equipment, materials and raw materials at all stages of manufacturing.

Peculiarities of the technological process

Milk production begins with purification using filtration equipment such as centrifugal separators, where cream is stored after purification and used as an additive to create the desired fat content. The separated and heat-treated milk is free from foreign substances. It is then pasteurized and the cream is added. The fat content of the milk is normalized automatically with the skimmer.

When the cream is added to the milk, the fat in the milk collects as large droplets. The droplets are reduced to the right size to prevent them from accumulating on the surface. Grinding is carried out in the homogenization process, but it is not necessary in the production of pasteurized milk, but it is mandatory in sterilization. The final stage is pouring milk into different containers (cardboard, plastic or other), applying the date of manufacture and shelf life.

Production of dairy products

All production processes relating to the production of products from milk (cottage cheese, kefir, yogurt etc.) are divided into two main groups: primary and secondary processing.

Primary is purification, cooling, separation or homogenization, pasteurization.

Secondary is with the use of microorganisms or enzymes. Microorganisms are used to make kefir, sour cream, cottage cheese, cheese, and sour milk.

Basic equipment for the production of dairy products

Producing dairy products requires specific equipment to ensure high-quality products and efficient production. Here are some examples of basic equipment used in the production of dairy products:

- Pasteurizers: Pasteurizers are used to heat milk to a specific temperature for a specific period of time to destroy harmful bacteria and extend the shelf life of dairy products. There are several types of pasteurizers, including batch, continuous, and high-temperature, short-time (HTST) pasteurizers.

- Separators: Separators are used to separate cream from milk and to remove any impurities from the milk. There are several types of separators, including disk separators, clarifiers, and centrifugal separators.

- Homogenizers: Homogenizers are used to break down fat particles in milk to create a more uniform texture and prevent separation. Homogenizers can be high-pressure or ultrasonic, and they can be used in conjunction with pasteurizers.

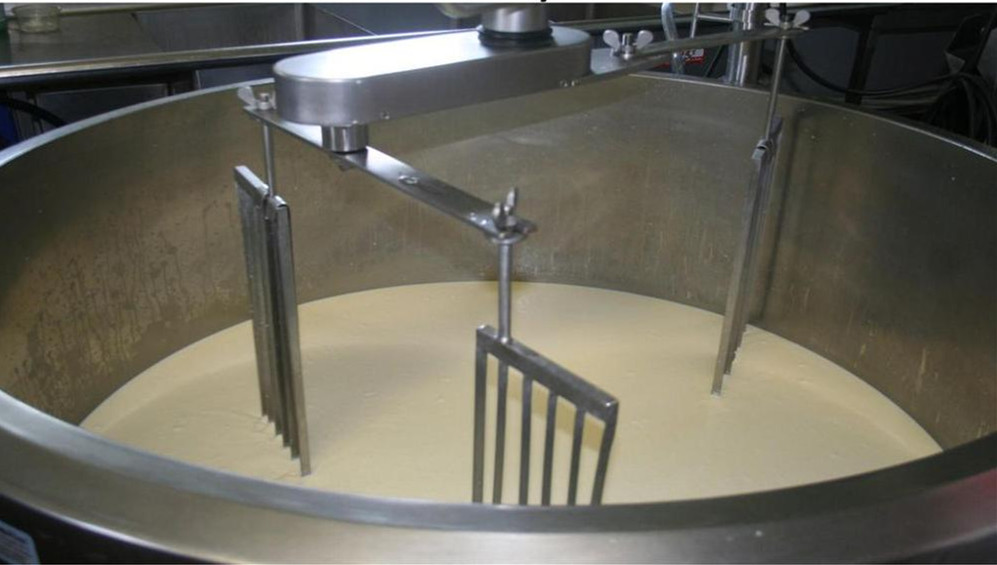

- Cheese vats: Cheese vats are large tanks used to heat and curdle milk to make cheese. Cheese vats can be made from stainless steel or other materials and can come in a range of sizes and shapes.

- Cheese presses: Cheese presses are used to press excess liquid out of cheese to create a firmer texture. Cheese presses can be manual or automated and can come in various sizes and shapes.

- Butter churns: Butter churns are used to agitate cream until the fat separates from the liquid to create butter. Butter churns can be manual or automated and can come in various sizes and shapes.

- Packaging equipment: Packaging equipment is used to package dairy products into various containers, including bottles, cartons, and bags. Packaging equipment can be automated or manual and can come in various sizes and shapes.

These are just a few examples of the basic equipment used in the production of dairy products. The specific equipment needed will depend on the type of dairy products being produced and the scale of the operation. It’s important to select equipment that meets your specific needs and that is designed for the highest levels of efficiency, quality, and safety.

Additional equipment for dairy production

In addition to the basic equipment, there are also other pieces of equipment that can be useful in dairy production, depending on the specific needs of the operation. For example:

- Milk tanks: Milk tanks are used to store and transport milk from the farm to the processing plant. They come in various sizes and shapes, and can be made from stainless steel or other materials.

- Milk pumps: Milk pumps are used to move milk from one location to another in the processing plant. They can be used to move milk between tanks, from the pasteurizer to the homogenizer, or from the separator to the cheese vats.

- CIP systems: CIP (clean-in-place) systems are used to clean equipment without disassembling it. This saves time and reduces the risk of contamination.

- Temperature sensors: Temperature sensors are used to monitor the temperature of milk as it moves through the processing plant. This is important for ensuring that milk is heated and cooled to the correct temperature during pasteurization and other processes.

- pH meters: pH meters are used to monitor the acidity of milk during cheese production. This is important for ensuring that the cheese has the correct texture and flavor.

- Membrane filtration systems: Membrane filtration systems can be used to separate milk into its components, such as proteins, fats, and sugars. This can be useful for producing specialized dairy products.

When selecting equipment for a dairy plant, it’s important to consider the specific needs of the operation, including the volume of milk being processed, the types of dairy products being produced, and the level of automation desired. It’s also important to consider the cost of the equipment, as well as its efficiency, safety, and reliability. By carefully selecting the right equipment, dairy producers can ensure high-quality products and efficient production.